Radial Gear Chamfering – RAZ FAZ

• Fulfilment of drawing specifications for (almost) all components

• Short processing times

• Short set-up times and therefore little downtimes

• Low acquisition costs for tools and clamping devices

due to standard interface

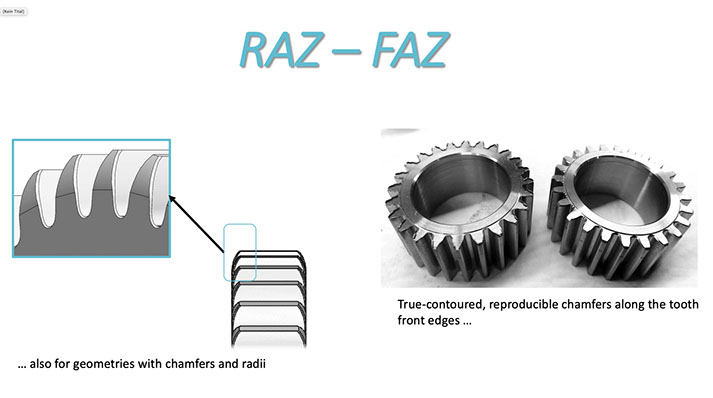

Radial chamfering

Machining of gears, also with coarse burr from the previous gear hobbing process.

A defined and repeatable chamfer is machined on the tooth front edges in the shortest possible time.

3 - 3

<

>

RGC 350 chamfering machine

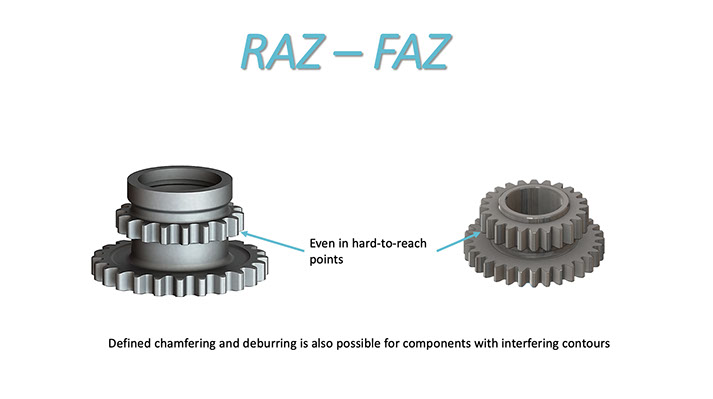

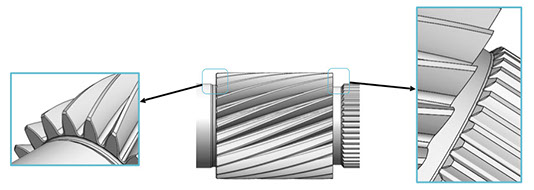

The RGC 350 chamfering machine has been developed together with the Radial Gear Chamfering process and is therefore precisely tailored to its requirements. With the RGC process, defined, reproducible chamfers can be produced at the tooth front edges, even on workpieces with interfering contours, such as multiple toothings and/or shaft shoulders, etc. The RGC process is also used for the production of the radial gear chamfering.

The chamfering process is carried out continuously with high cutting speeds in an environmentally friendly and economical way in dry cutting – thus you achieve short cycle times with a minimum footprint and a maximum working space at the same time.

With the RGC 350, workpieces with a maximum diameter of 350 mm and a maximum workpiece length of 350 mm can be machined.

Facts about the RGC 350

Short changeover times, < 15 minutes

Convenient and simple operation thanks to the intuitive user interface developed specifically for the process

Automatic tooth gap position detection

Short peak times, thus relieving bottlenecks during deburring

Extremely compact machine, footprint approximatly 2 m2

Installation of the automation solution that meets your requirements

Together with our partner bs Gruppe we can offer you a fully automated system for the defined chamfering of gears from one source!

<

>

RGC milling cutter

The workpiece-specific RGC milling cutters are optimally designed by us for your workpiece and your chamfer requirements. It goes without saying that we take into account the economic efficiency of the tool manufacture as well as of the application in the overall process through high cutting values and nevertheless long service life.

With the solid carbide end mill tools, gears with hard-to-reach points can also be chamfered and deburred in a defined, repeatable and reliable manner.

From tool design to production, the complete process is in our hands. Thus we can always guarantee you high quality and continuous improvements of the tools.

ToolFlowManagement

In addition to the design and manufacture of the tools, we will soon also offer you the complete logistics of tool procurement as well as reprocessing and procuring of replacement.

Please contact us if you are interested or have any questions.

Chamfering of internal gears

Next step – coming soon.

Please contact us if you are interested or have any questions.